BMW Custom Differential FAQ

Looking into having your diff upgraded? Here you will find all of the answers to your questions. Still have a question, drop us an e-mail or give us a call.

What is the process for buying a diff?

It's easy! Differentials are built from the specs you choose on the order. Each diff is custom-built by a diff specialist. You choose the gear ratio, limited slip upgrade, and any other options and submit your order.

What's the core charge?

If we build a diff from our stock a core charge will apply. If a core charge applies, it may be refunded after you send in your original diff and it is inspected. Cores

must be received back within

15 days of when you receive the diff. If you send in your original diff first, the core charge may not apply (depending on the condition of the diff you send in).

See below for complete information on cores.

Ring & Pinion / Gear Ratio Options.

All of our diffs are built with a final drive gear of your choice. For better acceleration select a shorter gear set (higher number = shorter gear). Most manual transmission cars have a tall gear. And most automatic transmission cars use a shorter gear set to offset the transmission ratios and heavier weight. The shorter the gear the higher the revs will be for any given speed. You don't want to go too short because it will leave you with higher revs on the highway, shifting more often, an extra shift in quarter-mile and acceleration runs, etc. This can also impact your fuel efficiency and also engine and road noise. Consider your gear choice carefully and remember we can always give you advice via phone or e-mail. We offer all of the factory gear ratios as well as some BMW Motorsport designed gear sets for certain models. We can also have the ring and pinion set polished to reduce friction and lower temperatures.

What is REM Polishing?

REM(tm) is a process where high spots and imperfections are removed from the surface. We offer polishing for the ring and pinion and the bearings. These imperfections are a normal byproduct of the manufacturing process and BMW does perform a basic finish to ensure there are no major defects. For a regular street car with regular service intervals the BMW-finished part works just fine. But there is always a little more that can be done, especially with precision machining, and this is where REM(tm) polishing comes in. Under extreme conditions these imperfections can create stress risers and localized hot spots and deformation of the material, which will accelerate wear and create more residual heat throughout the diff. REM(tm) polishing removes these high spots and imperfections and leaving a mirror smooth finish behind. The parts are given a chemical treatment and then ground with a very fine ceramic media. The grinding is gentle and designed only to take off high points on the surface and not to dig into the material itself. It's a 'micro polishing' multi-step procedure with proven results.

Benefits of REM(tm) finishing:

- reduced friction, vibration, and noise

- improved engagement

- longer life and less stress and fatigue

- lower temperatures

How To Check Your Current Gear Ratio

Not sure of your current diff ratio or think it was changed in the past? There are several ways to tell which ratio is currently installed -

Mark the input shaft and the diff housing together (paint marker, scribe, etc). Similarly mark an output shaft flange and housing. Spin the input shaft, which will turn the output flanges, and count the number of revolutions on the output flange until the markings on the output flange line up again. If the input flange spins 3.25 turns around then the ratio is 3.25:1. If it takes 4 turns then it's likely 4.00 or 4.10. You'll have guess to a certain degree (for instance it's hard to distinguish between 3.38 and 3.46) but you should be able to get an accurate range of what ratio is installed in your car. You can also spin it 10 times the normal number to get a more accurate gear ratio (41 turns = 4.10; 38 turns = 3.80; etc). The original ratio may be cast into the diff housing but that's no guarantee that someone didn't already change it.

Limited Slip Options.

Limited Slip units fall into two general categories: street-only use, mixed street-track, and full race use. The street LSD units are similar to most OE BMW LSDs - a 2 or 3 disc clutch-type with limited lock-up (up to 60%). These work great for regular street and daily driver use as they are simple, effective, reliable, and priced accordingly. The small number of clutch packs means heat can be a factor on grip and wear so high horsepower cars may want something stronger (OS Giken, Quaife, or helical). The performance of a factory-type LSD is simple, long-lasting, quiet, and predictable and you can expect it to perform just like it would have come from the BMW factory. Variable-lock diffs generally work best on the street but are not the ideal setup for track use.

Street/Track-type diffs are more complex with multiple clutch plates or with helical-style gears (no clutch plates). Because of their complexity they require special care and maintenance with more frequent oil changes with special fluid and periodic rebuilds. There may also be noise considerations depending on the type you choose. Track setups are dictated mainly by the track you're running on with gearing, ramp angles, and lock-up the major determining factors. It may be beneficial to have more than one diff for use at different tracks (as long as rules allow). A variable lock diff may be the best answer unless wheel spin is part of your handling setup. However, variable diffs can also alter the handling behavior of the car from one corner to another, making the handling unpredictable. If you have found the stock M Variable diff to be problematic on the track then we would suggest you switch to a more traditional 2 or 3-disc limited slip which will be more reliable. We can also build limited slip diffs with ramp angles that match your driving style and the track. Our race team used the OS Giken LSD in our E46 M3 and E92 M3 racecars.

Limited Slip Ramp Angles.

Limited Slip Ramp Angles.

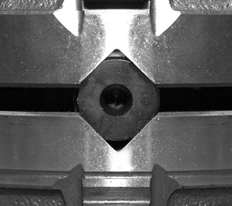

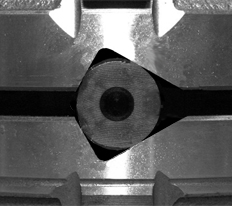

The ramps are machined sections of the limited slip housing that the spider gear pin rides on. The pin slides up and down the ramps to engage or disengage the clutch packs. The angle of the ramp determines how much and how quickly the LSD locks up. The higher the ramp angle (degrees) the more resistance there is and the less likely the diff will lock. A shallower angle will get the diff to lock quicker. There are ramps for acceleration and deceleration. Typically the decel ramp is very mild unless it's a full race setup. The factory LSD units are set at a 45* angle for accel and decel. We can vary the ramp angle depending on the car, useage, and driving style. We can even have an "adjustable" ramp angle design with multiple ramp angle options.

|  |

| typical factory BMW 45/45 ramp angles | custom 30/60 ramp angles

(not actual design, used for illustrative purposes only) |

One of the big advantages of a traditional clutch-type or helical LSD over the M Variable diff is there is no wasted motion in the LSD. When slip is detected the mechanical diff will instantly transfer load to the other wheel. In the M Variable viscous diff there is a delay as wheel spin happens first and then the diff begins to lock up.

Note that ramp angle and lock-up are two completely different things and they are expressed differently. Ramp angle is literally the angle from horizontal that the ramp follows. The lock-up is expressed as a percent. It's the percentage of torque that is distributed to the wheel with the most grip. An open (non-LSD) diff will distribute all of its torque to one wheel and that wheel will likely spin/slip under power. A LSD will transfer "XX%" of that torque to the wheel that is not spinning.

Limited Slip Lock-Up

As mentioned above the lockup is a percentage of torque transferred to the slower spinning wheel to gain better traction. The higher the percentage the more torque will be transferred during a loss of traction. The M Variable diff varies the torque based on wheel speed differences - the faster one wheel spins the more lock is given to the other wheel. Up to 100% of torque is transferred which is where the "variable" comes from. Traditional limited slip diffs have a fixed acceleration lock-up. The factory LSD is 25% lockup. We can vary the lockup based on the car and the type of driving you do. The downside to too much lock is that it pushes the car straight and will force understeer. That works great for a drag strip where you never turn but terrible when using the car on a road course where the wheels must spin at different speeds or an autocross course where some wheelspin is needed for the car to rotate.

What is replaced when my diff is rebuilt?

The first thing that is done is to clean all of the parts thoroughly. Differentials are very messy and cleaning all of the parts will make defects and wear more noticeable. We replace all of the seals, bearings, and hardware. On limited slip units the clutch discs and friction discs are heat treated and nitride coated. On M Variable diffs the viscous pump is inspected and tested. All internals are inspected and replaced if worn or damaged. Some parts get re-used as they are low or no-wear pieces. Our diff specialist also shims and aligns the diff correctly, which is absolutely crucial. This is actually the most time-consuming portion of the build becaufse it has to be just right. We take the time to build and check all of the correct clearances and tolerances to ensure the complete diff functions just as it should. The diff does not work properly if it's not built right and if you're not happy with the final result then we won't be either. You're getting back a diff that is effectively brand-new and maybe built a bit better than even a factory rebuild!

How long does it take?

How long does it take?

Each diff build is different. The typical turn-around time is less than 5 days. But for 'simple' diff builds we may be ready to ship sooner. If you select the gear polishing or other custom options it may add several days to the build time. We stock all of the common rebuild parts so parts shortages are not an issue. In rare cases, we may have to order a new part from BMW and that can take additional time. The diff build process involves significant manual labor (repeated assembly and disassembly to check clearances) and other setup. During busy times of the year we may experience some backups in the build process. In the event there is a prolonged delay, you will be notified.

How is a diff shipped?

We ship by UPS Ground. Air options are available as well but diffs are very heavy and shipping costs are high. Freight shipping is not required. We over-pack every diff in a double-core box with foam padding to ensure it makes it to your destination without damage or delay. The packaging is so robust you can usually re-use the shipping box and foam packing to send in your core. You can re-use the box and the foam packing but use new tape on the top and bottom to seal it. Every diff ships without fluid and without a cover.

What is the break-in?

What is the break-in?

Immediately upon installing your diff, drive the car slowly to a safe and appropriate location. At no more than idle speed drive 20 figure-8 patterns (full lock-lock on the steering). Then drive in 20 full-lock turns to the left and 20 more to the right. For the next 1,200 miles do not exceed 85 MPH and drive moderately, using care not to shock or load the driveline. Perform an oil change at 1,200 miles using appropriate fluid. During the break-in period it will be normal to experience clunking and chattering from the diff. There may also be a diff whine which will diminish over time. For street cars we typically recommend a 30,000 mile oil change interval. Track cars have a very different schedule and is based mainly on use and setup. OS Giken and 3-disc diffs should have oil changes every 15-20,000 miles. Kaaz differentials have their own break-in procedures and fluid recommendations.

What fluid should I use?

We prefer the Red Line or Motul brands as that is what we have had success with over the last twenty years. We also have a selection of factory Castrol or Pentosin fluid and the special OS Giken required fluid.

All of the 2 or 3-clutch limited slip units can use a 75/90 (normal street), 75/110 (aggressive street/light track), or 75/140 (heavy track) diff fluid. The heavier fluid is typically only needed on track-driven or drift cars.

A factory M Variable limited slip should only use the factory Castrol SAF XJ + FM booster.

OS Giken limited slips require their own 85W250 operating fluid.

Quaife torque biasing differentials can use a 75/90 fluid from Red Line or Motul.

Core Charge Policies

The Core Charge applies when we build a diff from our supply of differentials and parts. To ensure we have adequate diff supplies on hand we place an additional charge on your order. As an incentive to send us your original diff, all or part of that core charge may be refunded. Cores

must be received back within

15 days of your receipt of the new diff. Cores returned after the

15 days may not be accepted for refund. It is important that we receive your core promptly so that we can count on having good stock on hand for our future customers. Core charges may seem like an additional upfront cost for you but it ensures we have re-useable parts. Without these re-useable parts we would have to use new parts from BMW which will make the diff builds more expensive for everyone. And shipping your core back to us quickly ensures you do not pay credit card interest on the core charge. Core diffs must be complete except for the parts required for you to re-install the new diff. In other words, you must return a diff equal in components and accessories to the one we sent you. Things like input and output flanges must be returned as these are cleaned and re-used in our diff rebuilds. Critical parts that are missing from your core diff will be deducted from your core refund.

Limited Slip Cores: The following only applies to these models: E24, E28, E30, E36, Z3

As most of our differential builds include limited slip units we need original limited slip units returned to us. Non-limited slip (open) differentials returned for cores will not receive a full refund.

Returns.

Sorry, there are no returns on custom built differentials but we stand behind our products and will work with you to resolve any and all issues. Our expertise means there is no diff issue that can't be resolved.

All of our diffs are built with a final drive gear of your choice. For better acceleration select a shorter gear set (higher number = shorter gear). Most manual transmission cars have a tall gear. And most automatic transmission cars use a shorter gear set to offset the transmission ratios and heavier weight. The shorter the gear the higher the revs will be for any given speed. You don't want to go too short because it will leave you with higher revs on the highway, shifting more often, an extra shift in quarter-mile and acceleration runs, etc. This can also impact your fuel efficiency and also engine and road noise. Consider your gear choice carefully and remember we can always give you advice via phone or e-mail. We offer all of the factory gear ratios as well as some BMW Motorsport designed gear sets for certain models. We can also have the ring and pinion set polished to reduce friction and lower temperatures.

All of our diffs are built with a final drive gear of your choice. For better acceleration select a shorter gear set (higher number = shorter gear). Most manual transmission cars have a tall gear. And most automatic transmission cars use a shorter gear set to offset the transmission ratios and heavier weight. The shorter the gear the higher the revs will be for any given speed. You don't want to go too short because it will leave you with higher revs on the highway, shifting more often, an extra shift in quarter-mile and acceleration runs, etc. This can also impact your fuel efficiency and also engine and road noise. Consider your gear choice carefully and remember we can always give you advice via phone or e-mail. We offer all of the factory gear ratios as well as some BMW Motorsport designed gear sets for certain models. We can also have the ring and pinion set polished to reduce friction and lower temperatures.

REM(tm) is a process where high spots and imperfections are removed from the surface. We offer polishing for the ring and pinion and the bearings. These imperfections are a normal byproduct of the manufacturing process and BMW does perform a basic finish to ensure there are no major defects. For a regular street car with regular service intervals the BMW-finished part works just fine. But there is always a little more that can be done, especially with precision machining, and this is where REM(tm) polishing comes in. Under extreme conditions these imperfections can create stress risers and localized hot spots and deformation of the material, which will accelerate wear and create more residual heat throughout the diff. REM(tm) polishing removes these high spots and imperfections and leaving a mirror smooth finish behind. The parts are given a chemical treatment and then ground with a very fine ceramic media. The grinding is gentle and designed only to take off high points on the surface and not to dig into the material itself. It's a 'micro polishing' multi-step procedure with proven results.

REM(tm) is a process where high spots and imperfections are removed from the surface. We offer polishing for the ring and pinion and the bearings. These imperfections are a normal byproduct of the manufacturing process and BMW does perform a basic finish to ensure there are no major defects. For a regular street car with regular service intervals the BMW-finished part works just fine. But there is always a little more that can be done, especially with precision machining, and this is where REM(tm) polishing comes in. Under extreme conditions these imperfections can create stress risers and localized hot spots and deformation of the material, which will accelerate wear and create more residual heat throughout the diff. REM(tm) polishing removes these high spots and imperfections and leaving a mirror smooth finish behind. The parts are given a chemical treatment and then ground with a very fine ceramic media. The grinding is gentle and designed only to take off high points on the surface and not to dig into the material itself. It's a 'micro polishing' multi-step procedure with proven results.